Imagine 100% productivity of your rice mill machine

December 2, 2024

How to Choose the Right Machinery- Commercial or Mini Rice Mill?

January 1, 2025Indian Rice Mill Machines: A Game Changer for Africa’s Growing Rice Sector

Before we deep dive into the analysis of rice mill machines and mini rice mills in the African Rice Market, let's understand the local scenario there.

In Africa, rice accounted for approximately 3.8% of the main crop yield and 4.7% of the global rice production. Despite its current modest share, the demand for rice in sub-Saharan Africa is increasing at over 6% annually due to population growth, urbanization, and changes in consumer preferences, surpassing any other staple food.

The top 5 rice producing countries in Africa are- Nigeria is the largest rice producer. Followed by Egypt, Madagascar, Côte d'Ivoire (Ivory Coast), Mali. The emerging rice markets are Uganda, Rwanda & Kenya.

Why Africa is a Strategic Location for Rice Production

-

Availability of arable land and water resources. Africa has vast expanses of land available for rice cultivation and huge water bodies that can be tapped into for irrigation.

- Government Initiatives: The African Government has come up with various incentives to boost local rice production like Uganda National Rice Development Strategy (UNRDS) & Competitive African Rice Initiative (CARI).

Challenges to overcome

Over the past decade, Africa’s rice-growing area has expanded by nearly 40%, yet average yields have stagnated. Average yields in Africa are lower because of lack in appropriate agronomic management. By adopting sustainable modern farming techniques, introducing the right rice milling machines in the process, African countries can achieve better productivity.

The rice industry in Africa holds immense potential, but its growth is hindered by several factors.

1. Infrastructure limitations:

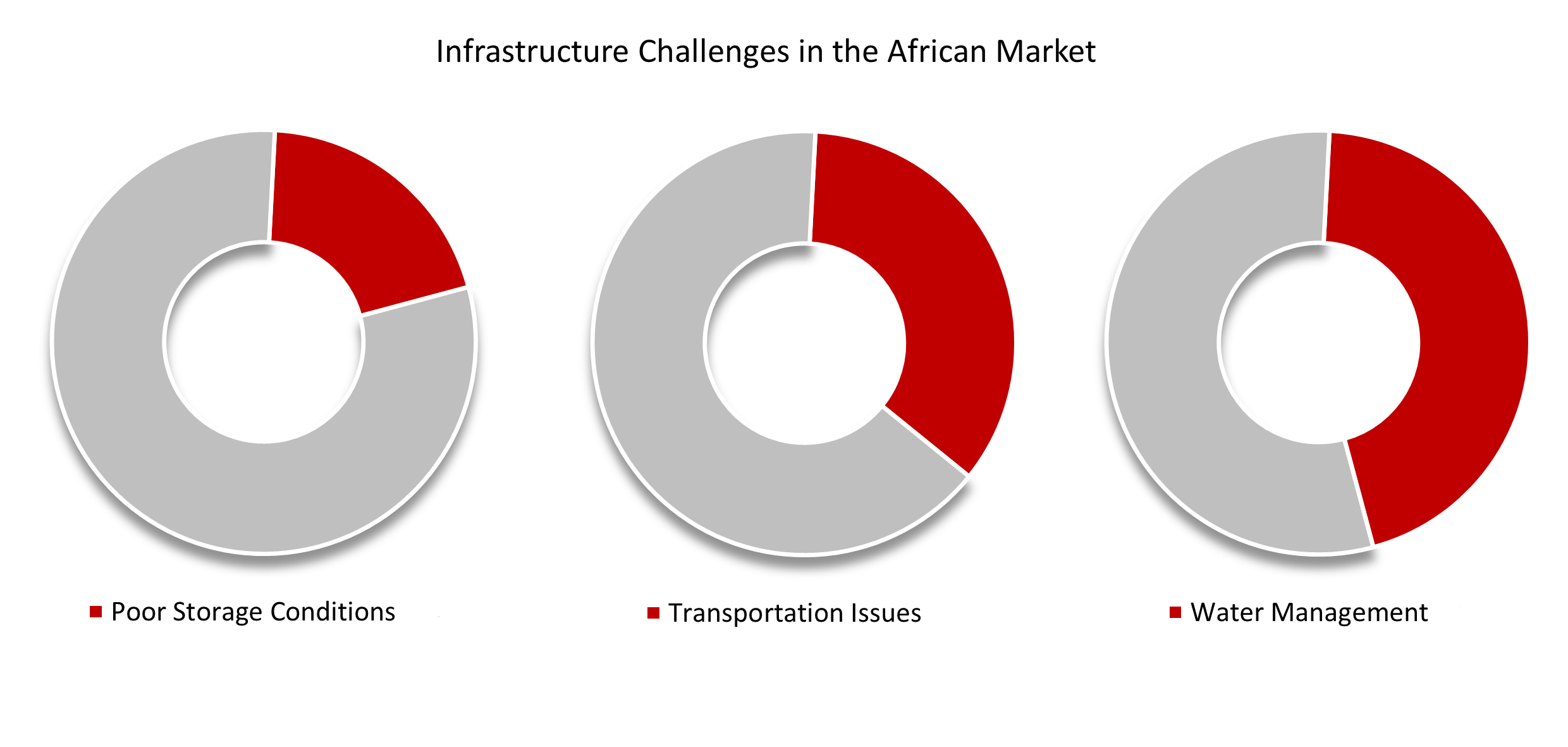

Infrastructure is one of the most significant obstacles, yet one of the easiest to address in the African Rice Industry. Transportation Issues: Lack of well-developed transportation networks, makes it difficult to move paddy to rice mills or finished products to markets. Poor road conditions and high logistics costs further hinder competitiveness. Mobile rice mill machines could be a viable solution, allowing processing to occur closer to farms and reducing transportation needs.

Storage Challenges: A lack of modern storage facilities leads to significant post-harvest losses. It reduces quality and market value. Introducing compact and cost-effective mini rice mills with integrated storage solutions can help local farmers process and store rice efficiently. Irrigation and Water Management: Although Africa has vast arable land, irrigation infrastructure is limited. Farmers often depend on unpredictable rainfall, leading to inconsistent yields. Indian companies can introduce drip irrigation systems and water-saving methods tailored to rice cultivation. Read more here for irrigation solutions.

2. Competition from Local and International Players:

The African rice market is becoming increasingly competitive. Local Producers are pushing for self-sufficiency in rice production, with government support for local farmers and small-scale processors. Introducing affordable and efficient mini rice mills can help companies differentiate amongst each other. Asian Exporters from China, Thailand, and Vietnam dominate the industry by offering low-cost rice that is hard to compete with. Adopting Indian advanced rice milling machines will improve yield and grain quality.

The Role of Indian Companies in Bridging the Gap

India is one of the largest producers of rice in the world, contributing significantly to the global rice trade.

- India's expertise in agriculture and rice production technologies- India’s extensive experience in the rice industry has led to the development of cutting-edge technologies, including advanced rice milling machines and mini rice mills, designed to maximize efficiency and minimize waste. Indian rice mill machines are known for their durability and cost-effectiveness.

- Experience in setting up sustainable rice production and processing facilities- Sustainability is at the heart of Indian agricultural practices. India has Energy-efficient rice milling machines which reduce energy consumption, making them ideal for regions with limited electricity. As most of Africa’s rice cultivation happens in the uplands, they can implement Water-saving irrigation techniques developed by India. It can help African farmers optimize water usage.

Indian companies have demonstrated their ability to adapt and thrive in international markets, particularly in agriculture. One such notable example is:

Olam International

While headquartered in Singapore, Olam leverages Indian agricultural expertise in several African countries. They have implemented rice processing facilities and used Indian rice milling technologies to improve productivity and quality.

Conclusion

The rice industry in Africa is poised for transformative growth, driven by rising demand, favorable climatic conditions, and increasing government and private sector investments.

Indian companies, with their expertise in agriculture and advanced technologies can introduce sustainable practices, affordable rice mill machines, and compact mini rice mills, they can help bridge the demand-supply gap, empower local farmers, and modernize rice processing across the continent.