Dairy Industry

February 8, 2024

Rice Processing

February 8, 2024WHEAT & MAIZE PROCESSING

Considering that raw material costs constitute a major expenditure in the milling industry, our primary objective is to achieve high yield and exceptional quality. We offer comprehensive support encompassing solution design, onsite installation, staff training, and repair and maintenance.

Our focus is to address critical concerns in the milling industry, such as maintaining consistent grind quality and effectively managing equipment wear and tear.

LINE DESIGN CRITERIA

Scale of Production

Form of Processing

Packaging Type & Design

BASIC PROCESS FLOW

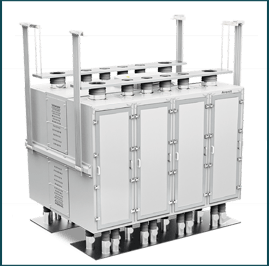

STAGE 1- CLEANER

STAGE 2- ROTARY SEPERATOR

STAGE 3- DESTONER

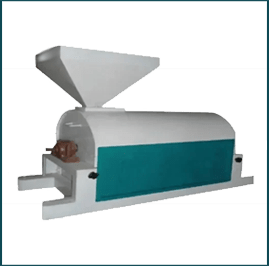

STAGE 4- EMERY ROLLER

STAGE 5- ASPIRATION

STAGE 6- PULVERISER

STAGE 7- HAMMER MILL

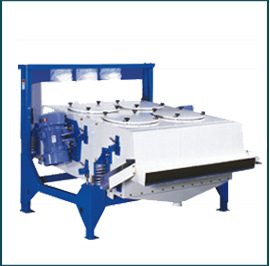

STAGE 8- PLAN SIFTER

STAGE 9- ENTOLETER

STAGE 10- PACKING

Connect with us now to get Customised Solutions