Understanding Rice Breakage: Causes and Solutions

February 17, 20255 Ways India Can Help Rice Mills in Ghana

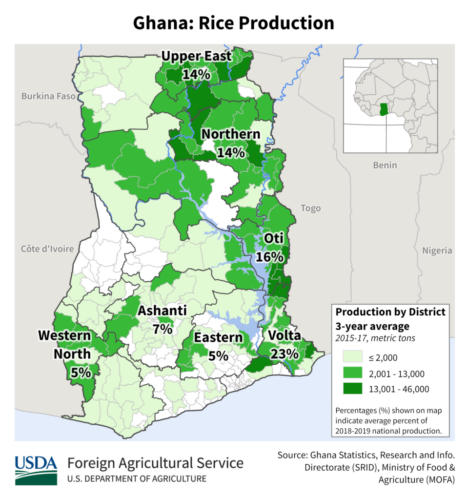

While key players of Rice Industry are spread out in Nigeria, Egypt and Ivory Coast, countries like Ghana and Uganda are upcoming.

Ghana's rice industry is experiencing rapid growth, driven by increasing local demand and efforts to reduce dependency on imported rice.

Efficient rice milling is crucial to meet this demand while ensuring high-quality output and minimal losses. Indian expertise in rice milling machines presents a strategic solution for Ghana, offering advanced technologies, cost-effectiveness, and tailored solutions for diverse local needs. Generally speaking, a complete set of rice milling plant integrates rice cleaning, dust and stone removal, milling and polishing, grading and sorting, weighing and packaging, etc.

Located in the eastern part of Ghana, the Volta Region has a leading figure in Ghana’s rice production arena. According to the US Department of Agriculture (USDA)*, the region contributes about 23% of Ghana’s total rice production.

The Significance of Indian Expertise in Rice Milling

India has long been a global leader in rice production and processing. With decades of innovation and manufacturing experience, Indian companies have developed rice milling solutions that are not only efficient but also adaptable to varying conditions. Their machines have been successfully implemented across Asia, the Middle East, and now increasingly in Ghana, proving their versatility and reliability.

Read how the Indian companies understand and capitalize the challenges and opportunities of the African market for a mutually beneficial and long standing business relationship.

Advantages of Indian Rice Mill Machine for Africa

Cost-Effectiveness

Affordable technology suited for small to large-scale producers. Indian rice milling equipment is more affordable than many Western alternatives, making it accessible for both small-scale farmers and large-scale industrial operations in Africa. Operational and maintenance costs are kept low due to durable designs and locally available spare parts.

Technology and Innovation

Advanced technologies include automated grading, polishing, and sorting systems. Energy-efficient designs reduce electricity consumption, which is critical for areas with high energy costs or limited access to power.

Customization and Scalability

Machines can be tailored to process various African rice varieties, ensuring optimal results for different grain types. Scalable systems allow businesses to expand their operations without significant additional investment.

Durability and Reliability

Indian machines are built to withstand tropical climates and challenging environments. High-quality materials ensure a long lifespan, reducing the need for frequent replacements.

Knowledge Transfer and Training

Indian manufacturers provide comprehensive training programs for African operators, ensuring efficient use and maintenance of the equipment. Knowledge transfer helps local communities build technical expertise, empowering them to manage and repair the machines independently. Continuous support is often offered through service agreements or remote assistance, reducing downtime.

Conclusion

Indian expertise offers a well-rounded solution for Africa’s rice milling challenges. By leveraging cost-effective, reliable, and customizable technologies, African rice producers can enhance their operations and contribute to food security. The collaboration with Indian manufacturers also fosters knowledge transfer and skill development, creating a sustainable foundation for growth in the rice industry.