Rice Mill Machine Sustainability : Role of Regular Maintenance

January 28, 2025

Why Indian Expertise for Rice Mill in Ghana?

February 17, 2025Understanding Rice Breakage: Causes and Solutions

The rice mill machine used and it's maintenance greatly influences the output of the mill. The quality of rice plays a crucial role in market demand and profitability for producers. However, one of the most common challenges faced in the rice industry is the problem of broken rice grains. This issue directly impacts the economic returns of rice millers and exporters.

In this blog, we will explore the causes of rice breakage, how it can be minimized, and the role of modern rice mill machines in ensuring high-quality output.

The Science Behind Rice Breakage

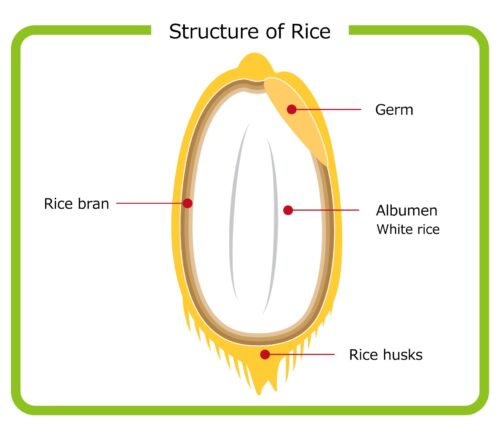

Rice grains can break during processing, primarily in the milling stage. To understand this better, let's examine the structure of a rice grain:

- Hull: The outermost layer that

protects the grain.

protects the grain.

- Bran: The layer beneath the hull, rich in nutrients.

- Endosperm: The inner part, which is the edible portion.

Breakage occurs when the grain's structure is unable to withstand mechanical forces during milling. This results in fractured grains, which are less valuable in the market.

Common Causes of Rice Breakage

- Varietal Characteristics: Certain rice varieties are naturally more prone to breakage due to their physical and chemical composition. Long-grain varieties, for example, are more susceptible to breaking than medium- or short-grain types.

- Moisture Content: Improper moisture levels in paddy during milling are a leading cause of breakage. High moisture can make the grains too soft, while low moisture makes them brittle.

- Parboiling Process: Inconsistent or poorly managed parboiling can weaken grain structure, leading to breakage during subsequent processing stages.

- Poor Milling Equipment: Outdated or poorly maintained rice mill machines exert uneven pressure on grains, increasing the risk of breakage. Read our top input on maintaining rice mill machines to improve life of the mill and quality and quantity of the output.

- Improper Dehusking: Excessive force applied during the dehusking process can lead to cracks in the grains, which later result in breakage.

- Over-polishing: Excessive polishing to achieve a shiny appearance can weaken the grains, causing them to break.

- Mechanical Stress: Improper alignment or settings in the milling machinery can introduce unnecessary mechanical stress, breaking the grains.

- Storage and Handling Issues: Rough handling or improper storage conditions before milling can lead to cracks in the paddy, resulting in broken grains.

Solutions to Minimize Rice Breakage

1. Selecting the Right Variety:

Choose rice varieties that are less prone to breakage and suitable for the intended market. Hybrid varieties with improved milling yields can also be considered.

2. Optimizing Moisture Content:

- Maintain a uniform moisture content of 12-14% in paddy before milling.

- Use advanced drying systems to achieve consistent moisture levels without damaging the grains.

3. Improving Parboiling Practices:

- Invest in modern parboiling equipment to ensure uniform steaming and drying.

- Monitor temperature and duration during parboiling to maintain grain integrity.

4. Upgrading Milling Equipment:

4. Upgrading Milling Equipment:

- Invest in state-of-the-art rice mill machines designed for precise operations.

- Regularly inspect and maintain equipment to ensure optimal performance.

5. Calibrating Dehusking Settings:

- Adjust the dehusker to minimize force applied to the grains.

- Use rubber roller technology for gentler dehusking.

6. Optimizing Polishing:

- Avoid over-polishing by understanding market requirements.

- Use advanced whitening and polishing machines that exert controlled pressure.

7. Training and Skill Development:

- Conduct regular workshops to ensure the workforce stays updated with best practices.

8. Proper Storage and Handling:

- Store paddy in well-ventilated, moisture-free environments.

- Use automated systems for grain handling to reduce physical stress.

Role of Modern Rice Mill Machines

Modern rice mill machines are revolutionizing the industry by reducing breakage rates and improving yield. Here are some of their key features:

- Pre-Cleaners: Remove impurities like stones and husks, ensuring smooth milling operations.

- Rubber Roll Dehuskers: Provide gentle handling of grains, reducing cracks during dehusking.

- Paddy Separators: Efficiently separate paddy from brown rice, minimizing losses.

- Whitening and Polishing Machines: Ensure even polishing with minimal stress on grains.

- Grain Graders: Classify grains based on size and quality, removing broken rice effectively.

- Automation: Advanced machines come with sensors and AI technology to monitor and adjust processes in real-time.

Conclusion

Minimizing rice breakage is essential for maximizing profitability and meeting quality standards in the rice industry. By understanding the underlying causes and implementing modern solutions, including advanced rice mill machines, producers can significantly reduce breakage rates. Investing in the right technology, training, and processes not only ensures better yields but also strengthens your market position in a competitive industry.