Commercial Rice Mill in Africa : Transforming with Automation

January 8, 2025

Rice Mill Machine Sustainability : Role of Regular Maintenance

January 28, 2025This blog delves into the essentials of combine harvesters, their role in the rice industry, and how they contribute to the success of turnkey projects.

The rice industry is a cornerstone of agricultural economies worldwide, particularly in regions like Africa, where demand for staple food crops continues to grow. As automation spearheads the growth in this sector, it is imperative to understand and leverage advanced agricultural machinery. Amongst the various machines available to adopt technology and minimize costs, the combine harvester (after implementing tractors) stands out as a game-changer, offering unparalleled efficiency and productivity. The interesting thing about Combine Harvesters is, that its’ use is not restricted to the rice industry particularly, but can be applied to various other grains.

What is a Combine Harvester?

Combine harvesters come in various sizes and configurations, catering to different types of farms and terrains. A combine harvester is a versatile machine designed to efficiently harvest a variety of grain crops, including rice. They have become indispensable in modern agriculture due to their ability to handle large-scale operations with ease.

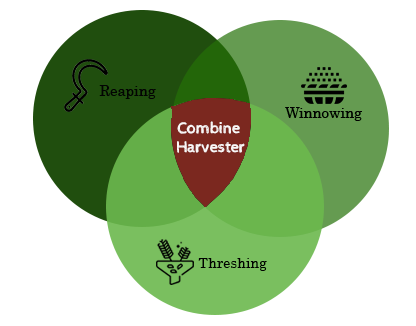

The term “combine” reflects its ability to perform three critical harvesting operations simultaneously:

1. Reaping: Cutting the mature crop.

2. Threshing: Separating the grains from the stalks.

3. Winnowing: Cleaning the grains by removing chaff and debris.

Key Components of a Combine Harvester

Understanding the components of a combine harvester can help consultancy firms recommend the most suitable models for their clients:

1. Header: Cuts and gathers the crop. Headers vary depending on the type of crop and terrain.

2. Threshing Drum: Separates grains from stalks through impact.

3. Concave: Works with the threshing drum to loosen grains.

4. Separator: Removes grains that might still be attached to the stalks.

5. Cleaning System: Includes sieves and fans to clean the grain.

6. Grain Tank: Stores the cleaned grain.

7. Chopper/Spreader: Distributes leftover stalks or straw back into the field.

8. Operator’s Cabin: Houses controls for steering and managing machine functions.

Benefits of Combine Harvesters in Rice Farming

1. Efficiency and Speed

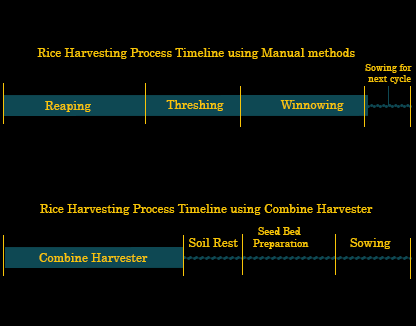

Combine harvesters significantly reduce the time required for harvesting. In regions like Africa, where manual harvesting dominates, the introduction of combine harvesters can slash labor costs and time by up to 70%. Timely harvesting allows time for seed bed preparation and sowing for the next production cycle.

2. Cost-Effectiveness

While the initial investment in a combine harvester might seem high, the long-term savings in labor and increased yields outweigh the costs. These machines also reduce dependency on seasonal labor, ensuring uninterrupted harvesting operations. Studies show a saving of upto 65% in labor in implementing mini-combine harvester.

3. Improved Grain Quality

The cleaning and winnowing features of combine harvesters ensure minimal grain damage, leading to higher market prices. Their precision also minimizes grain losses, which is particularly beneficial for farmers in developing regions. Ali et al. (2018) reported that harvesting loss of rice can be reduced 5.12% using mini-combine harvester in comparison to manual harvesting system.

4. Adaptability to Varied Conditions

Modern combine harvesters come equipped with adjustable features to handle different terrains and crop types, making them ideal for Africa’s diverse agricultural landscapes. Whether dealing with wet fields or dry plains, these machines deliver consistent performance.

5. Environmental Benefits

By efficiently chopping and spreading straw, combine harvesters promote better soil health. This practice reduces the need for burning residual crop matter, which is a common practice that contributes to air pollution.

Combine Harvesters and Turnkey Projects in Africa

1. Addressing Labor Shortages

With urbanization drawing labor away from agriculture, mechanization through combine harvesters can fill the gap, ensuring timely harvesting. This is especially critical in Africa, where farming communities often struggle with limited manpower.

2. Boosting Productivity

For turnkey projects aiming to establish large-scale rice farms, combine harvesters enhance productivity by streamlining the harvesting process. These machines allow operators to harvest vast areas efficiently, meeting both local and export demands. Follow these tips to maximize productivity in your commercial rice mill.

3. Economic Impact

Efficient harvesting translates to reduced post-harvest losses, higher yields, and better income for farmers. These benefits align with the goals of consultancy firms striving for economic upliftment in African communities.

4. Integration with Modern Farming Practices

Turnkey projects often integrate advanced agricultural practices (link to agriculture industry), such as precision farming. Combine harvesters equipped with GPS systems and yield monitors can provide valuable data to optimize farming operations.

Factors to Consider When Choosing a Combine Harvester

Crop Type: Ensure the harvester is suited for rice and can handle specific field conditions.

Field Size: Larger fields require harvesters with bigger headers and tanks to maximize efficiency.

Terrain: Tracks might be preferable over wheels in wet, muddy conditions to avoid getting stuck.

Cost and Maintenance: Balance between upfront cost and long-term maintenance expenses. Ensure the availability of affordable spare parts.

After-Sales Support: Availability of spare parts and service centers is crucial for long-term reliability.

Fuel Efficiency: With rising fuel costs, opting for fuel-efficient models can reduce operational expenses.

Ease of Use: Machines with intuitive controls and automated features are more user-friendly and reduce training costs.

Challenges and Solutions

Challenge: High Initial Investment

Solution: Leverage government subsidies or financial aid programs designed to promote mechanization in agriculture. Encourage farmer cooperatives to pool resources for shared machinery.

Challenge: Skill Gap

Solution: Conduct training workshops for operators to maximize machine efficiency. Partnering with companies to provide comprehensive training programs can also ensure smooth operations.

Challenge: Limited Access to Spare Parts

Solution: Establish partnerships with your project managers to ensure a steady supply of parts and after-sales support. Local assembly plants or dealerships can bridge this gap.

Challenge: Environmental Concerns

Solution: Promote sustainable practices, such as using straw choppers and spreaders, to minimize environmental impact. Some models now feature reduced emissions technology to align with global environmental standards.

The Future of Combine Harvesters

With advancements in technology, the next generation of combine harvesters is set to revolutionize agriculture further. Features like GPS-guided systems, IoT connectivity, and AI-driven operations are making these machines smarter and more efficient. Autonomous harvesters, powered by renewable energy, are also under development, promising a greener future for farming.

For consultancy firms involved in turnkey projects, staying ahead of these trends ensures delivering cutting-edge solutions to clients. By adopting such innovations, clients can achieve sustainable growth and long-term profitability.

Conclusion

Combine harvesters are more than just machines; they are catalysts for transformation in the rice industry. By adopting this technology, turnkey projects in Africa can achieve higher efficiency, better yields, and sustainable economic growth. As a consultancy firm, understanding the intricacies of combine harvesters equips you to provide informed recommendations, ultimately driving success for your clients.

If you’re looking to incorporate combine harvesters into your rice project, contact us today for expert guidance tailored to your specific needs.